Nutech Powder Coating Is Pleased To Introduce Our State Of The Art Custom Powder Painting Line

- 725 feet conveyor lenght

- Operation speed variable 3-15 feet per minute

- Four stage stainless steel wash

- Large phosphate cleaning

- First Large Rinse

- Second Large Rinse

- Alodine 4500 heated stage for the treatment of Aluminum, Galvanise, Galvalume, architectural products and mild steel

- 190 feet cure oven(two pass)

- Designed to handle parts of 25 feet length

- Urethane, Epoxy, Polyester, Hybrid and Super Durable Coatings

- Paint Booth-Stainless steel, complete with recovery system and dust collector

- Batch booth for painting sample pieces and custom work

- We offer pick up and delivery services

- Fast and efficient turn around time(24 to 48 hours)

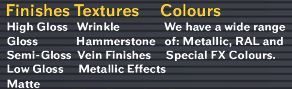

All orders are customized to your specifications. You choose the colour, finish, and texture.

In Depth Clean

Parts Preparation: Parts are inspected and any imperfections are removed.

Cleaning: Parts are moved to our treatment and cleaning area, where they are go through our four stage stainless step wash with a hot high-pressure washer.

Iron Phosphate: The parts are iron phosphated to provide an etched surface for the powder to adhere to. Which helps to provide a superior bond between the powder and the metal.

Dry Off: Parts are then rolled into a batch oven and dried using the drying cycle on our continuous conveyor.

Powder Coating: Once the parts are dry they are moved to the powder booth where powder is electro statically applied.

Powder Cure: Parts are baked in one of our ovens until they are cured.

Packaging: The finished product is wrapped and packaged ready for shipment.